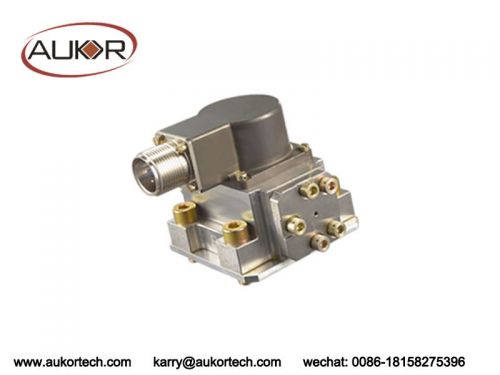

F07 Series Double Nozzle Flapper Force Feedback Servo Valves

|

Alerta de Segurança

|

| #275165 |

|

14 Vezes

|

|

Denunciar Anúncio

|

Descrição do anúncio

ID: #1898599

Usuário: #275165

Finaliza: 16/03/2026 em 27 dia(s)

Localização: São Paulo - São Paulo - Jardim Taquaral

F07 Series Double Nozzle Flapper Force Feedback Servo Valves

Features:

• F07 Series as a Replacement for MOOG 760 Series

• High precision control, fast dynamic response and ease of operation.

• Stainless steel body, high structure strength.

• Compact structure, small size and light weight.

• Stable performance, high reliability and long working life.

• Low internal leakage and low power consumption.

• Low hysteresis, high threshold and high repeatability precision.

• Excellent linearity, driving force and small null shift.

Applications

• Remotely operated vehicle

• Automated guided vehicle

• Animatronics

• Manipulators

• Downhole tools

• Entertainment

Operation Principle:

F07 Series Servo Valves has a polarized torque motor, which consists of 2 charged permanent magnets, armature assembly, upper and lower polepieces and 2 coils. In the torque motor two pieces of permanent magnets polarize uppers and both ends of its armature are respectively inserted into the gaps formed by upper-and lower polepieces. A flexture tube is employed to play the role not only in a spring support for the armature-flapper assembly but also in a sealing between electromagnetic and hydraulic parts. The flapper of the first stage hydraulic amplifier is inserted between two nozzles, forming two variable orifices.A feedback spring extends from flapper inner and inserts its ball end in the small slot of the spool.

When electrical current input is applied to the torque motor coils, due to the interaction between controlling and permanent flux, a magnetic torque is created on the armature. This torque makes the armature-flapper assembly rotate about the flexure tube support, moving the flapper in one direction or in another direction.The moved flapper results in increasing the area of one flapper-nozzle orifice and decreasing the area of the other one,creating

differential pressure in the two nozzle controlled chambers. This differential pressure moves the spool, pushing the ball end of feedback spring and creating restoring torque on the armature-flapper assembly. The spool goes on moving until the feedback torque becomes equal to the magnetic torque caused by control current input At that time,the flapper is moved back to a neutral position.As the magnetic torque is proportional to the current input. And the feedback torque is proportional to the spool position as well, therefore, the spool position is proportional to the input current while the mentioned torques are being balanced. Then, with constant valve pressure drop, valve flow output to load is proportional to current input when rectangular holes (slots) or annular grooves are employed in the valve bushing.

Dimension: 99x99x73mm

Weight: 1400g

Mechanical interface:ISO 4401: 2025

Vibration:3 axis, 30g, 5-2000Hz

Working temperature:-30 … +100℃

Storage temperature:-40 … +80℃

Ambient temperature:-55 … +150℃

Fuel temperature:-40 … +120℃

Maximum operating pressure: 280Bar

Rated current:15-40mA

Coil resistance:80-200Ω

Hysteresis:<4%

Threshold: <1%

Linearity:<7.5%

Symmetry:<10%

Pressure gain:>30%

Null bias:<3%

Lap:<2.5%

Null shift with supply pressure (80%~110%)Ps:<2%

Null shift with return pressure (0~20%)Ps:<2%

Null shift with temperature change of 56°C:<4%

Frequency response @-3dBAmplitude ratio:>50%

Frequency response @-90° Phase lag:>50%

Insulation resistance:>50MΩ

Hydraulic oil:DIN52524-Part 1 ...Part 3 / ISO11158

Recommend viscosity:15-100cSt

Fluid viscosity:5-400cSt

Rated flow rate Q,ΔP=35 bar: 63L/min, 100L/min

Internal Leakage @210bar:<3L/min(F06,F07)

Cleanliness class recommended for functional safety:NAS 1638: 5, ISO 4406: 14/11

Recommended cleanliness class for a longer service life:NAS 1638: 4, ISO 4406: 13/10

EM compatibility: EN61000 - 6 - 2,EN55011:2016+A1

Electrical interface: EN175201-804

Signal:+/- 10mA,+/- 20mA,+/- 40mA

Bushing Spool Design:4-way, Zero Lap,Linear characteristic

PN: F07S63BMCH4PN