E1 Series Electro-hydraulic Servo Actuators

|

Alerta de Segurança

|

| #275165 |

|

28 Vezes

|

|

Denunciar Anúncio

|

Descrição do anúncio

ID: #1898612

Usuário: #275165

Finaliza: 20/03/2026 em 31 dia(s)

Localização: São Paulo - São Paulo - Jardim Taquaral

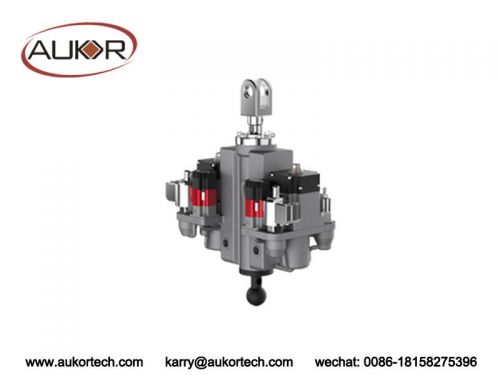

E1 Series Electro-Hydraulic Servo Actuator

Introduction:The Electro-Hydrostatic Servo Actuator (EHSA), or electro-hydraulic servo actuator, is an advanced actuation device critical for aircraft and aerospace equipment. As a distributed independent hydraulic device without needing a central hydraulic power source or pipelines, it converts electrical energy to hydraulic energy via an electric motor driving a hydraulic pump (with power controlled by regulating pump output flow through variable-speed motors with fixed-displacement pumps or fixed-speed motors with variable-displacement pumps) and then to mechanical energy through pressurized hydraulic oil acting on a hydraulic cylinder to drive aircraft components like flight control surfaces, landing gears, and engine parts. EHSAs are developing toward miniaturization, lightweight design, compact structures, and high power-to-weight ratios, with ongoing optimization to meet evolving equipment requirements and advance technology.

AUKOR lightweight electro-hydraulic actuator (EHA) is based on the independently developed rotary direct-drive servo valve. It adopts a servo motor to directly drive the servo valve core, thereby achieving precise control. Suitable for multiple technology-intensive fields such as aerospace, it has certain guarantee capabilities in terms of safety. The integrated molding technology adopted makes its overall structure more compact, and reasonable; under the same working pressure and flow conditions, the overall weight is reduced by up to 60%. It also effectively reduces the risk of hydraulic oil leakage and significantly improves the stability and reliability indicators of the system. In addition, it features customizable design capabilities and can be designed into single, dual, or redundant structural forms according to the needs of different application scenarios to meet diverse safety requirements. While ensuring reliable operation, it realizes efficient power output, providing a highly competitive solution for high-end drive and precise control in various industries, and occupies an advantageous position in the future development trend. Whether it is to meet the strict requirements for equipment in the aerospace field or adapt to the needs of high-precision and lightweight power systems in other industries, it can perform excellently.

Principle:

· Conversion of Electrical Energy to Hydraulic Energy:An electric motor drives a hydraulic pump to pressurize the fluid for the hydraulic actuator. The power output of the actuator is controlled by regulating the output flow of the pump. Common methods include using a variable-speed motor to drive a fixed-displacement hydraulic pump or a fixed-speed motor to drive a variable-displacement hydraulic pump.

· Conversion of Hydraulic Energy to Mechanical Energy:Pressurized hydraulic oil acts on the hydraulic cylinder, causing the cylinder to move locally at the actuator. This realizes the output of mechanical energy and drives the movement of relevant aircraft components, such as controlling flight control surfaces (elevators, rudders, ailerons, flaps, slats, spoilers, etc.), extending and retracting landing gears, positioning engine inlet guide vanes and thrust reversers, and opening and closing cargo compartments or weapon bays.

Features

· Flexible: Suitable for position, speed and pressure control.

· Reliable: Optional dual redundancy design, single fault no multi-actuator failure.

· Energy-Saving: Low leakage, low pressure loss, and high pollution resistance.

· High-Quality: Anti-oil leakage, dustproof, waterproof, internal anti-corrosion, and long lifespan.

· Precise: High frequency response, small hysteresis ultra-high position & force control accuracy.

· Compact: Integrated cylinder + pump body + valve body + oil tank, easy to install and maintain.

Applications

· Aerospace Vehicles: Surfaces control, retraction/extension of landing gears, tiltrotor control, hybrid power control, weapon pylon control, launch mechanism control, and pod control

· Ship Control Systems: Ship rudders steering, windlasses control, watertight doors opening/closing, thrusters angle adjustment, lifeboats lifting, cranes lifting, anti-roll fins action.

· New-Energy Electric Vehicle: Steering control precisely, brake boosting, autonomous driving, power transmission, energy recovery, pre-collision braking, vehicle loss-of-control rescue, active suspension shock absorption, seats multi-dimensional adjustment, intelligent control of in-vehicle environment.

· Robots: Motion control, force feedback, compliance control, human-machine interaction scenario support, environment adaptation and flexibility control; movement and operation in harsh environments, and precise control operations.

· Construction Machinery: Control of excavator boom; control of crane hoisting, luffing and slewing mechanisms; optimization of loader shoveling; control of bulldozer blade.

Main Components

· Safety Valve

· Displacement Sensor

· Pressure Tap

· Electromagnetic Check Valve

· Rotary Direct Drive Servo Valve

· Controller Plug

· Drive-integrated Servo Motor

· Piston Rod

Dimension: 262.6x133x360.5mm

· Rated thrust (N) 17,000

· Maximum working stroke (mm) 60

· Rated speed (mm/s) 10

· Repeat positioning accuracy (mm) 0.01

· Total power consumption (W) 200 + 200

· Working voltage (Vdc) 24

· Hydraulic Cylinder

· Cylinder bore specification (mm) 28

· Stroke (N) 160

· Maximum thrust (N) 17,000

· Maximum pulling force (N) 12,000

· Maximum speed (mm/s) 100

· Electric Motor

· Voltage (Vdc) 18 ... 36

· Power (W) 500

· Pump

· Displacement (cc) 0.5

· Pressure (Bar) 110

· Environment and Testing

· Protection IP65

· Working temperature range (°C) -40 ... +65